Making Massive, Diesel Power With Fleece Performance Engineering

This article was published on June 28, 2018 by Bradley Iger and Diamond Pistons:

Fleece Performance Engineering has become synonymous with serious high performance diesel builds. The Brownsburg, Indiana shop is the brainchild of brothers Chase and Brayden Fleece, who took their passion for making big diesel power and created one of the most respected outfits in the country.

When it comes to diesel high performance, boost is the name of the game. Big, multi-turbo setups are commonplace, both in competition and out on the street.

In recent years, Fleece Performance Engineering has become synonymous with serious high performance diesel builds. The Brownsburg, Indiana shop is the brainchild of brothers Chase and Brayden Fleece, who took their passion for making big diesel power and created one of the most respected outfits in the country for racers looking to build championship winning trucks for drag racing and sled pulling. But these days, Fleece Performance Engineering is just one element of the operation.

Benshoof tells us that Freedom Racing Engines has been using Diamond pistons from the outset. He says To work with a company like Diamond, who is vested in making a good product, is vitally important to us.

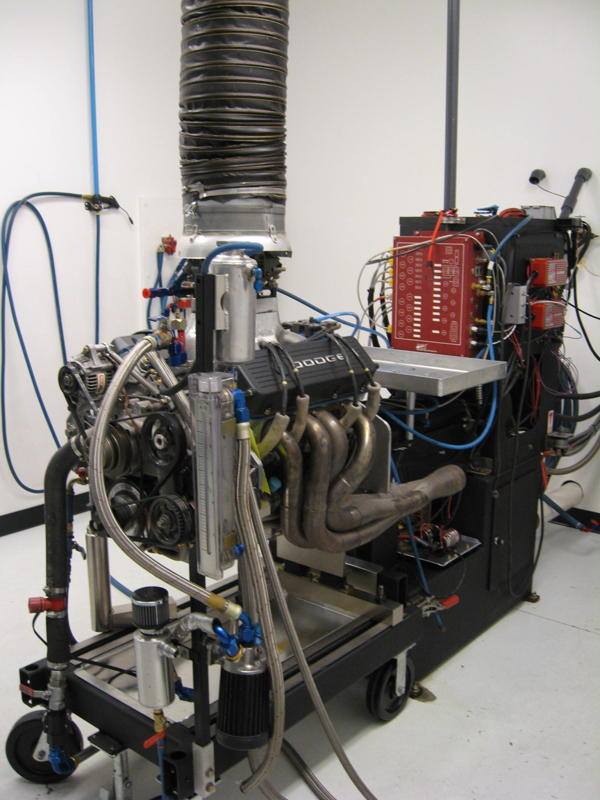

“Fleece is an aftermarket diesel performance parts manufacturer,” Chase explains. “So we build everything from turbos to injection pumps and electronics through our drive-in service shop. Fleece puts together engines for competition vehicles like our puller truck, and those engines come from Freedom Racing Engines, which is right across the street. So basically Freedom is the engine building side and Fleece is the tuning side.”

“Before Chase and Brayden took over, Freedom mainly specialized in block repairs and gas engine builds,” says Freedom Racing Engines shop manager John Benshoof. “When they started bringing blocks over to get machine work done, they eventually struck a deal with the former owner, who was looking to retire. These days the builds generally fall into two main categories: Street truck applications, which we like to say is a “trickle-down effect” from the big competition stuff, and the guys who need engines for sled pulling competition and drag racing. We’ve also repair quite a few blocks for NHRA Top Fuel and Funny Car teams.”

Along with their involvement in the Ultimate Callout Challenge series, Fleece also campaigns a truck in the Lucas Oil Pro Pulling League series, along with NTPA and ITPA pulling classes.

And while Freedom Racing and Fleece Performance crank out builds for racers like Ryan Milliken, Chris Buhider, and Ben Shaddy, Chase also personally puts the companies’ work to good use out at the track. “I’ve always been a gearhead – from the time I was ten years old I was into go karts, ATVs, and motocross racing,” he tells us. “If it had an engine, we were messing with it. When I was around 18 I had a Cummins and an LS1 car and I eventually decided that, rather than focusing on the LS stuff, I’d go down the path of tuning Cummins engines.”

The team currently campaigns two trucks in competition. “We have our Ultimate Callout Challenge truck, which is a 2006 Dodge Ram 2500 that’s basically just a dyno queen that gets used in drag racing and some sled pulling, and we also have our 2005 Chevrolet Silverado Light Limited Pro 3.0 Smooth Bore truck, which is used in the Lucas Oil Pro Pulling League series, along with NTPA and ITPA pulling classes.”

Benshoof explained that during the early years of Fleece Performance they brought most of their machine work across the street to Freedom Racing Engines. Eventually Fleece struck a deal with Freedom’s owner to buy the engine shop, and now the two outfits directly support one another’s building and tuning efforts.

The Ram is outfitted with a 7.0-liter solid block Cummins mill with three 13mm Fleece PowerFlow 1000 injection pumps, a Hamilton camshaft, Freedom’s own racing cylinder head and two 102mm Garrett GT55 ball bearing turbos blowing into a 4.3-inch Weimer HX82 turbo. “The combination should easily lay down 2800 horsepower at the tire, so about 3500 horsepower at the crank,” Chase notes. “We’ve got the same dyno that the UCC has, so this winter, I’m going to be spending a lot of my time getting to where we can just dominate the dyno element of that series.”

With that kind of boost in the mix, Chase admits there’s been some bottom end carnage over the years, but they’ve honed in on a combination they’re happy with. “Freedom Racing has been using Diamond pistons since the beginning,” he says. “I’m not gonna lie to you – we’ve melted a fair amount of pistons over the years, but that’s been part of the learning process. We’ve worked closely with Diamond to dial-in the designs, and they’ve been great about getting us what we need in a timely fashion.”

Under the hood of Fleece’s 2006 Dodge Ram 2500 is a 7.0-liter solid block Cummins mill with two 102mm Garrett GT55 ball bearing turbos blowing into a 4.3-inch Weimer HX82 turbo. Chase tells us the setup makes in excess of 2800 rear-wheel horsepower.

That sentiment is echoed by Benshoof as well. “It’s been an ongoing work in progress to get a design that works well, can withstand the abuse, and we can make power with,” he explains. “To make that kind of power and to go to events where the truck gets run all out for three days straight like at UCC – where we made the most power out of any vehicle there – and be able to drive it on the trailer at the end of it is pretty impressive.”

Chase notes that while he typically changes out the slugs after each season as a rule of thumb, diesel racers like Milliken – who competes in X275 Radial drag racing with a turbocharged and nitrous fed 6.8-liter solid block Cummins under the hood of his ’66 Chevy Nova – are getting a lot of life out of the Diamond pistons in their Freedom Racing-built engines. “He’s a perfect example – this is the third season on that set of pistons and they’re still going strong.”

Benshoof says Freedom’s builds usually fall into one of two categories – racers who need competition-spec power, and enthusiasts who see those race trucks in action and want to significantly elevate the level of performance in their street-driven rides.

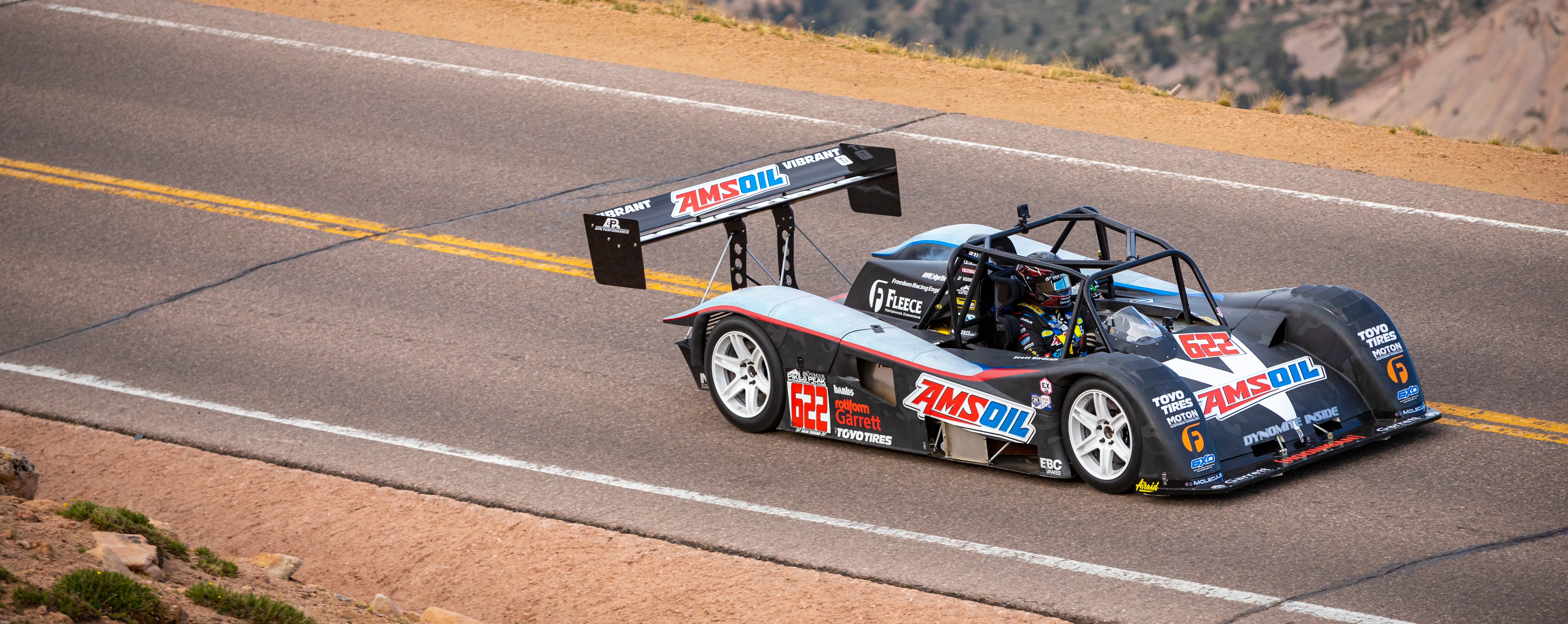

Fleece says while UCC competition pulled a lot of team’s resources from other efforts last year, this season they’re working on something new. “We have plans of running the rest of this season in the 5.90 index with the UCC truck. But now we also have the dragster, and we’re planning on campaigning that in the Outlaw Diesel Super Series so people can see it in action. That’ll be a 6.8-liter Cummins putting out between 2500 and 2800 horsepower, and we plan to be the first diesel-powered rail to get into the 3s in the eighth mile with it.”

A lofty goal no doubt, but Fleece has the resources and talent on hand to make it happen. “I’m fortunate enough to have three people on staff who are retired Top Fuel drag racers,” he adds. “These guys know how to go fast. So we’re going to go have some fun with it and work on getting all the power to the ground to get it there.”

Freedom Racing built the Cummins under the hood of Ryan Milliken’s ’66 Nova. The powerplant is an unusual sight amongst a field of gas-powered V8s in the X275 radial drag racing series.